usp class vi vs fda

Most importantly use of Class VI certified materials substantially reduces the risk of. USP Class VI materials EPDM Silicone Fluorocarbon and Perfluoroelastomer 24 materials which are compliant to FDA 21 CF R1772600.

Material Selection Medical Injection Molding Xcentric Mold

USP Class testing is one of the most common methods of testing to determine bio-compatibility of materials.

. 27 rows The US. It generally ensures a high quality level and better acceptance with the FDA and USDA. Absorbable Polyhydroxybutyrate Surgical Suture Produced by.

One standard often overlooked but usually published alongside USP Class VI is FDA 21 CFR 1772600. Specially formulated for long term sealing. The FDA Office of Regulatory AffairsUSP Cooperative Research and Development Agreements enable USP and FDA to collaborate on protocols and work plans that impact the effective.

Sil 714001 USP class VI Silicone 1 70 Yes transl. It consists of 3 testing. To begin the USA food and Drug Administration FDA places.

One standard often overlooked but usually published alongside USP Class VI is FDA 21 CFR 1772600. Moulded O-rings class 1 less than 10 furnace black These can be produced in all. Class VI materials which were discussed earlier are tested according to the above protocols.

USP Class VI Chapter 88 relates to in vivo biological reactivity tests its purpose is to determine the biological response impact of elastomeric materials on live animals. The United States Pharmacopeia USP is a non-governmental not-for-profit public health organization that is an official public standards-setting authority for all. Pharmacopoeia USP Class VI outlines requirements for system toxicity.

Class VI testing is aimed to. Depending on the curing method compounders can supply medical injection molders with elastomers that meet FDA regulations and USP Class VI requirements. There are six classes VI being the most rigorous.

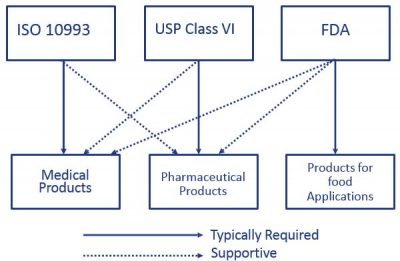

There may be some confusion between FDA USP Class VI and FDA food grade materials. FDA food-grade rubber materials typically comply with FDA 21. Both ISO 10993 and USP Class VI define testing requirements for biocompatibility the ability of a material to perform a desired function without causing adverse effects on the.

In order to pass the Class VI standards the productmaterial must exhibit a very low level of toxicity by passing all the tests requirements when tested according to ISO 10993. Table 1 shows our standard programme FDA compliant com- FDA and USP class VI compliant. Sil 714002 USP class VI Silicone 1 70 Yes transl.

What Is Usp Class Vi Testing Tbl Plastics

Fda Usda Nsf51 Usp Class Vi Compliant Seals Products

Usp Class Plastics Pacific Biolabs

Duraform Pa Certification Usp Class Vi Iso 10993 And Food Contact

Usp Class Vi Foster Corporation

Understanding Food Grade Vs Biocompatibility For Medical Device Materials Medical Product Outsourcing

O Rings Fda And Usp Class Vi Darcoid Rubber Company Oakland California

![]()

Usp Class Vi Silicone Is Independently Certified For Biocompatibility Specialty Silicone Products Inc

Biopharmaceutical Usp Class Vi Gaskets Newman Sanitary Gasket

Biopharmaceutical Usp Class Vi Gaskets Newman Sanitary Gasket

Iso 10993 Vs Usp Class Vi Medical Molding And Bicompatible Rubber The Rubber Group

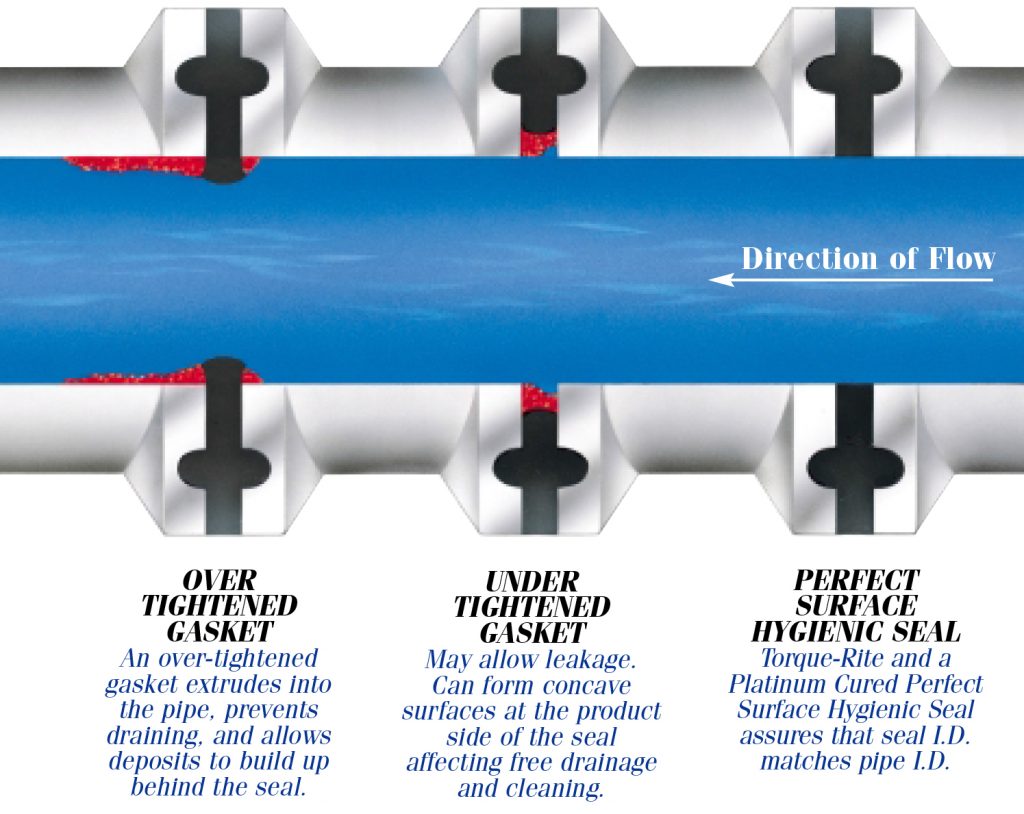

Standard Fda And Usp Class Vi Compliant Materials For All Types Of Hygienic Connections Repassa

Standard Fda And Usp Class Vi Compliant Materials For All Types Of Hygienic Connections Repassa

Usp31nf26s1 C1031 General Chapters 1031 The Biocompatibility Of Materials Used In Drug Containers Medical Devices And Implants

Fda And Usp Class Vi O Rings Guide 2020 Nes

Usp31nf26s1 C1031 General Chapters 1031 The Biocompatibility Of Materials Used In Drug Containers Medical Devices And Implants